Fatty Acid industry is associated with production of fatty acids and glycerine. Both vegetable oils & animal fats are being used as feedstock for fatty acids / glycerine manufacturing. The fatty acids are manufactured as a distillate mixture or a pure fraction. Pure fractions can be obtained either from fractionation plant or by selectively choosing the feed-stock & carrying out straight distillation.

Fat Splitting Plant

Mectech is one of the top Fat Splitting Plant Manufacturers in India and abroad. In Fat Splitting Plant, hydrolysis reaction of oil / fat is carried out. The reaction takes place at high pressure and high temperature. Triglycerides (fat/oil) react with water to convert into fatty acids and glycerol. The Fat Splitting Plant is a high-pressure single tower system. The fatty matter proceeding from battery limits is pre-heated and fed to the de-aerator operating under vacuum.

The de-aerated fat is fed via a high-pressure pump to the bottom of the tower. In bottom of the tower, there is a heat recovery section where de-aerated fat is heated by the exiting sweet water. The process water is fed via a high-pressure pump to the top of the splitting tower.

In top of the tower, there is a heat recovery section where process water is heated by the discharging crude fatty acids. The high pressure splitting tower is provided with temperature controllers.

Fatty Acids Distillation Plant

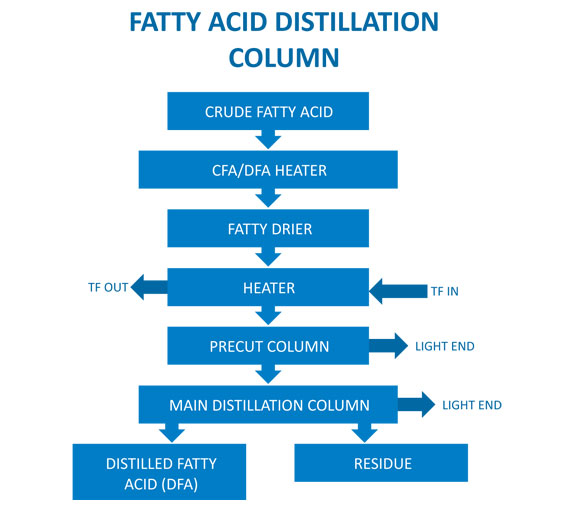

Mectech is a top Fatty Acid Plant manufacturer in India and abroad. Fatty Acids Distillation plant is broadly divided into three main sections. viz. de-gasification, pre-cut system and main distillation system. These main process sections are supported for optimum cooling based on thermostatised water system.

Crude fatty acids from battery limit is filtered, pre-heated and admitted to the de-gasifying unit operating under vacuum, where it is dried and de-gasified. Crude fatty acids, from de-gasifier is heated in thermic fluid exchanger and fed to the pre-cut column.

The pre-cut column operates under vacuum and is composed of various sections: starting from bottom, the main sections are vaporization section, two sections of distillation packing bed, pump-around section and scrubbing section. From bottom of the column, the product is sent to Fatty Acid Distillation column.

The main distillation column operates under vacuum and is composed of various sections; starting from bottom the main sections are vaporization section, stripping section, one set of washing section, one pump-around section and one scrubbing section

Soap Noodles

Fatty acids sourced from Palm Stearin, Rice-Bran Oil, Coconut Oil, Tallow, etc. are typically blended together to form fatty acids blend for soap manufacturing. Today all premium grade soaps are being manufactured from blend of the distilled fatty acid. Mectech’s Revolutionary on-line separation system for fatty acid and glycerine phase

Working principal

Driving force for Static Separator is gravity flow. The Separator is a static device having highly specialized internals and level controller. The internals are so specially designed that, the disperse phase smaller droplets gets agglomerate on the surface to form bigger globules. This enhances process of separation of the two phases.

The agglomerated bigger globules represents Free Disperse Phase and is padded through an environment where sufficiently quiescent conditions are maintained, so that disperse phase globule rises to the continuous phase surface; forming a layer of disperse phase liquid. The removal of both phases from the separator is through level controller. Both phases are freely discharged under gravity.

Fatty Acid Fractional Distillation

Fractional distillation is used for separation of Fatty acid mixtures into composite cuts or even individual components.

This process is used to produce high purityfractions offatty acids.

The fatty acids are fractionated in fractionation columns having structured packing which allow high separation efficiency and low pressure drop. Falling films are provided to gently evaporate the liquid phase and vapors are condensed in surface condenser. The operation depends on the feed composition or is based on the origin of raw material and the product fractions composition or purity. The number of fractional distillation column are selected and operated in series.