Your own independent On-Site supply of Hydrogen.

- Well Proven Electrolysis Technology

- 4,000 Units Working Satisfactorily Worldwide

- Minimal space required & Negligible Maintenance

- Continuous Online Purity Check

- Low Generation Cost, Low Power Consumption.

- Once started it can be left un-attended.

- PLC Controlled & Requires No Operator’s Attention

- Hydrogen Purity Up to 99.9999% Achievable

- Remote monitoring and control already proven in many references.

- In case of any abnormality the Generator would trip automatically with Audio Visual/Alarms for action.

- Skid-Mounted, Pre-commissioned at our works & Almost ready to use. Plug n play in small sizes.

- Customized engineering and Ability to custom design our large Hydrogen generator plants to your specific requirements.

- Long-term commitment to R&D utilizing integrated, fully-functional pilot facility.

- When Storage Tank Get Filled the Gas Generator Goes to Sleep & restarts once the pressure in Tank reduces to set Limit.

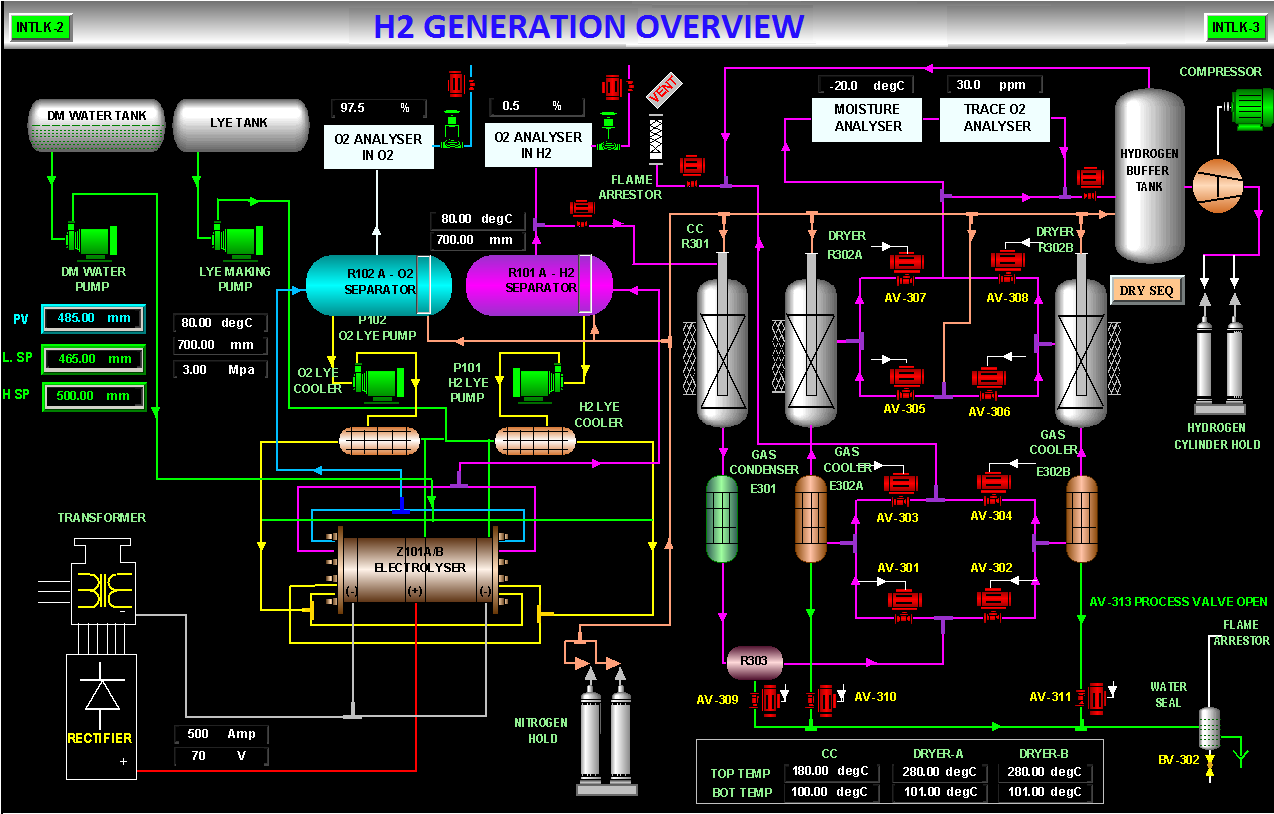

Process Description of the Pressurized Water Electrolysis System

The hydrogen Generator offered By Airox Nigen is based on Bipolar Pressurized Water Electrolysis Based System. The Electrolyser can be operated at a pressure of from 10 – 32 barg. Each electrolyser is designed for a capacity 10 % extra of desired final hydrogen flow. The Main equipment of hydrogen generator is electrolyser, in which, water is decomposed into hydrogen and oxygen through electrolysis, and the equation is :

2H2O —> 2 H2+O2

- The electrolyser we use is bipolar pressurized type.

- The cell of electrolyser is divided into anode cell and cathode cell.

- Hydrogen is generated on cathode side.

- Oxygen is generated on anode side.

- Electrolyser is filled with electrolyte KOH mixed with DM water (30% KOH).

- A Rectifier with Transformer is used to change high AC Voltage electricity to low AC voltage and then through rectifying by the rectifier to become DC power.

- The positive pole of DC power is connected to the anode of electrolyser, cathode of electrolyser is connected to negative pole

- Electrolyser is filled with electrolyte KOH mixed with DM water (30% KOH).

- A Rectifier with Transformer is used to chnage high AC Voltage electricity to low AC voltage and then through rectifying by the rectifier to become DC power.

- The positive pole of DC power is connected to the anode of electrolyser, cathode of electrolyser is conected to negative pole

Cathodic reaction is 4H2O+4e —> 2H2+4OH– Anodic reaction is 4OH – —> O2+2H2O+4e

- Once the DC current is passed in the elctrolyser while the electrolyte is being circulated the hydrogen and Oxygen are generated and are sent hydrogen and oxygen separators.

- In the Separators the hydrogen and oxygen are separated with electrolyte due to gravity and the electolyte come down .

- The pressure in the system is raised due to accumalated gas and is maintained at a set pressure by means of regulating valve.

- The electrolyte at the bottom of hydrogen and oxygen separators by gravity comes back and is pumped back to electrolyser after filtering and cooling, to complete the process cycle.

- While THe hydrogen gas is generated and is collected for further use , the Oxygen generated can also be collected for use seprately or allowed to be vented.

- The DM Water ( pressurized )is continuously fed to the Gas Separation Skid enabling make up of DM water used while generation.

- The Hydrogen Generated from electrolyser Is of 99.9 % pure and can be used for most of the applications.

- For higher purity, Hydrogen Purification is provided by which Hydrogen of 99.999% and a Dew Point of (-) 70°C can be achieved.

- Our Hydrogen Plant can be designed for a pressure of minimum 10 barg to a maximum of 30 barg. In case a higher pressure is required, an oil-free diaphragm type hydrogen booster can be provided.

OPERATING PRINCIPLES & PROCEDURE

- The system offered by us can be started by just switching on or stopped by switching off by one command through HMI.

- On a getting a Start Command the PLC checks the process variables of the system that must be within certain parameters before the program will execute and progress to a further phase.

- The start-up conditions can also become shut down conditions, if a start-up condition fails during the normal operation of the unit and finds the basic parameters are not in order giving you the audio visual signal on the PLC.

- When the PLC is first started, its program performs a form of self-diagnostic checking, including its own power supply ,sub modules , networking , network traffic , execution speed , serial ports etc before any other operations can be initialized.

- Only after the self diagnostic is completed successfully the plc starts further function , in case of any issue an alarm will be generated, an operator can take corrective action

- Once this is done , then the system is prepared to perform a Nitrogen Purge, provided conditions are correct and system is required to perform nitrogen purge

- Nitrogen is made available from a bank of few cylinder installed for purging and are all kept filled and at regulated pressure ready for purge however with isolation valve closed which needed to be opened manually when ever we like to perform nitrogen purge.

- Nitrogen purge is done if the plant was in shutdown condition for a long time This is in order to drive all the air from the system before hydrogen is permitted to enter. The program first checks what are called the Nitrogen Purge Start-Up Conditions i.e. the electrolyte levels, pressure and temperature are checked before the purge of the system can be started

- The conditions for nitrogen purge are different to those of hydrogen production due to the difference in the gases. Once a specific volume of nitrogen, enough to entirely purge the system has entered, the system progresses to the next stage, of Hydrogen Production.

- Before hydrogen production can begin and send for further purification and compression , the nitrogen in the system has to be replaced with hydrogen gas by process called the Hydrogen Purge.

- Once the hydrogen production is initialized and the purity required is achieved then the hydrogen is sent further for consumption. or if higher purity is required then it First goes to The Purification System and if higher pressure is required then it goes to The Booster Compressor, before it is send for consumption.

- During normal operation all the parameters are continuously monitored and recorded. parameters like pressure ,temperature, electrolyte flow rate, electrolyte level, DM water quality, purity of gas at dryer exit is all recorded and ensured that the gas and the equipment does not goes off specifications.

- System shut down can be performed whenever the plant is not needed to be operated. The shut down can be

- Normal shut down wherein you need to restart the system in a day or two.

- Emergency shutdown – due to fault generation or detected.

- Long shut down – wherein you do not need to use the plant for a longer time and then you need to purge out hydrogen from system and purge in nitrogen to keep it in safe shut down condition.

Safety Feature Of Hydrogen Plant

Hydrogen is a combustible gas, its combustion and explosive ranges are wide. In the air, its combustion and explosion ranges is 4.0~75 %(v/v) and 18.0~59%(v/v), in oxygen, they are 4.65~94% and 18.3~58.9%, the energy for firing is only 0.02mJ, the flame speed is 270cm/s. As Hydrogen is a dangerous gas to handle, we In order to meet the high safety requirements, design our system with utmost care and have incorporated Pressure, Temperature and Level Transmitters controlled by PLC. Pressure control – In normal operation, the control system monitors the pressure value, compares it with the set values, once the measured value crosses the set value, there will be a alarm signal enabling the operator to tackle the problem. If the problem is not solved timely and the pressure increases continuously, a High High Pressure signal come from the Overriding pressure transmitter which is interlocked to the rectifier and stops the rectifier to stop the generation of hydrogen. Considering the reliability, the signals for alarming and interlocking come from different instruments. Temperature control – The temperature control is important and critical as well, the temperature is also monitored by PLC, when the temperature overpasses the set value, it will alarm, when the temperature is higher than required, the control system will interlock the rectifier and open the regulation valve of cooling water to maximum position to reduce the temperature rapidly. Level control – The control system compares the measured values of hydrogen and oxygen level with their set values, once the values are beyond of the set ranges, the control system will alert the operator to tackle the problems, if the problems are not solved timely, the rectifier which is interlocked will trip . The Alarms and interlocks of level prevents the generation of explosive mixture of H2-O2 . All other equipments such as PLC, Rectifier, Power Panel, Motors, Pumps, Instruments etc. are adequately designed for reliable and safe operation.

Standard Scope Of Supply In Hydrogen Plant

- Electrolyzer unit (cell) – Medium Pressure, Bipolar sealed compact design to generate hydrogen, complete with all accessories

- Gas Separation Skid Consist of Hydrogen and Oxygen Gas separators to separate / remove electrolyte entrained with gas which mainly consists of:

- Hydrogen Gas Separator & Cooler

- Moisture separator At Hydrogen Gas Cooler

- Oxygen Gas Separator & Cooler

- Moisture Separator At Oxygen Gas Cooler

- Electrolyte Filter , Electrolyte Pump & Electrolyte Cooler

- Flame arrestors

- Interconnected piping

- Associated Instruments and drain & isolation valves

- DM water feed pump to pressurize the DM water periodically to the electrolyser

- Rectifier Panel complete with all accessories, rectifier, transformer, etc.

- Power and Motor Control Panel with Switchgears

- PLC Panel with User Defined HMI

- Optional Equipments

- Required For hydrogen purity of 99.999 %

- Hydrogen Gas purifier consisting of Palladium based Deoxo reactor with RTD.

- Automatic Change Over Valves with Associated Instruments and drain & isolation valves & Interconnected piping.

- Associated reactivation equipment and devices.

- Dual or Triple Tower Desiccant Dryer unit filled with high performance molecular sieve and with heaters and related RTD.

- Deoxo Cooler with Moisture Separator.

- Required for pressure above 30 Bar G ( Can Boost to 70 , 100 , 150 , 200 or 400 Barg or more as required )

- Oil Free Diaphragm Hydrogen Gas Compressors complete with

- Drive arrangement with Flame proof motor and V belts

- Suction Pot with Required Instrumentation Like Pressure Gauge , Pressure Switch

- Inter-coolers & Required Accessories

- Hydrogen Gas Cylinder Manifold with isolating valve, safety valve etc arranged for filling of hydrogen

- Gas Analyzing Sensors

- Online Moisture PPM – to measure Dew Point at final Hydrogen Discharge

- Online Oxygen Trace PPM – at final Hydrogen Discharge

- Hydrogen Leak detectors

Exclusions From Our Scope Of Supply

- All Civil Work for building & equipment foundation. However relevant load data & civil assignment drawings shall be provided by us.

- Handling arrangement for operation and maintenance.

- Any item not specifically offered by us and is not mentioned as option in this offer.

- Illumination / lighting of Hydrogen generation plant.

- Storage space at site.

- Ventilation and Air Conditioning system.

- Earthing for Hydrogen Generation Plant.

- Fire & lightning Protection for Hydrogen Generation Plant.

- Cable raceway system from H2 generation battery limit to purchaser equipment/system.

- Any other item/work which is not included in our offer