Why PSA Nitrogen From Airox Nigen

- Onsite Gas Generation

- Well Proven Pressure Swing Adsorption Technology

- More Than 15,000 Units Working Satisfactorily Worldwide

- Skid Mounted Pre-commissioned Ready To Use Units

- Fully Automatic Plant – Requires No Operator’s Attention

- Low Generation Cost – Pay Back Period Less Than A Year

- Negligible Maintenance No Hassles of Changing Cylinders

- Continuous Online Purity Check

- Nitrogen Purity Up to 99.9999% Achievable

The Technology

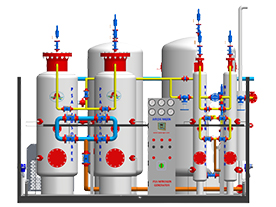

Our Nitrogen Generators operates on Pressure Swing Adsorption, commonly known as P S A Technology. P S A Technology is based on the selective adsorption phenomena of gas molecules under pressure on the surface of highly porous and efficient adsorbent.Achievable In this case of Nitrogen Generation the Adsorbent is Carbon Based Molecular Seive (C.M.S.). In P S A System when compressed air is passed through a adsorption tower field with CMS the molecules of oxygen, moisture & other unwanted gases are adsorbed on surface of C.M.S. and Nitrogen which is not adsorbed by C.M.S. comes out of adsorption tower and is collected in a surge vessel. For continuous generation of nitrogen two Adsorption towers are provided which are interconnected with Auto Change Over Valves and are controlled by PLC in the control panel. After saturation of one tower with oxygen, process automatically changes to another tower and thus nitrogen production is continuous. Our systems are the best ones in industry to ensure the highest efficiency, user friendly design, Reliable Economical and Durable. Our onsite nitrogen generators are custom made and can be adjusted to give the desired nitrogen quality for your process and application.

- Salient Features of PSA Nitrogen Generators.

- Operator and User Friendly design.

- Gas Generator are Skid mounted & Minimal space requirement.

- Proprietary CMS utilized.

- Pre-commissioned at our works Almost ready to use.

- Once started it can be left un-attended with Reliability of operation second to none.

- High efficiency operation (lowers your power costs).

- Your own independent on-site supply of nitrogen.

- These are fully automatic and require virtually no attention of the Operator.

- All operations take place automatically and Nitrogen Purity remains very consistent.

- In case of any abnormality the Generator would trip automatically with Audio Visual/Alarms for action.

- Offered by the leaders in Adsorption technology and largest manufacturer in the world

- Customized engineering to meet your process requirements. & Remote monitoring and control already proven in many references.

- Long-term commitment to R&D utilizing integrated, fully-functioning pilot facility.Ability to custom design our larger nitrogen generator plants to your specific requirements.

- When Storage Tank Gets Filled , Gas Generator Goes to Sleep and restarts once the pressure in storage Tank is Reduces to set Limit.

Membrane Technology for N2 Generation

A nitrogen membrane generator is designed to remove nitrogen from the atmosphere. This is accomplished by pushing compressed air through a set of polymer fibers. As the compressed air moves through the membrane, the nitrogen molecules are separated from the other molecules. Tiny microscopic holes in the membrane fibers allow oxygen to pass through and return to the atmosphere as waste gas: The nitrogen molecules are too large to pass through the microscopic holes; therefore, the N2 molecules are captured at the opposite end.

Nitrogen Cylinder Filling Station

An N2 filling station is the perfect solution for manufacturers who purchase bottled nitrogen. A nitrogen fill station from On Site Gas Systems, allows for easy cylinder refills. With an on-site nitrogen filling station, concerns related to running out of nitrogen gas and/or waiting for a delivery are in the past.

On Site Gas Systems offers its clients systems of the highest quality. All the systems On Site Gas Systems offers are designed to operate for decades. These systems are reliable even in the most remote locations around the globe, under the harshest climates and in a variety of hertz and voltage combinations. To learn more about the innovative products available, contact On Site Gas Systems today.