Rice bran oil is normally refined by physical method to keep the Oryzanol in the refined oil. In chemical process Oryzanol get destroyed by alkali.

Refining of Ricebran Oil

Rice bran oil is normally refined by physical method to keep the Oryzanol in the refined oil. In chemical process Oryzanol get destroyed by alkali.

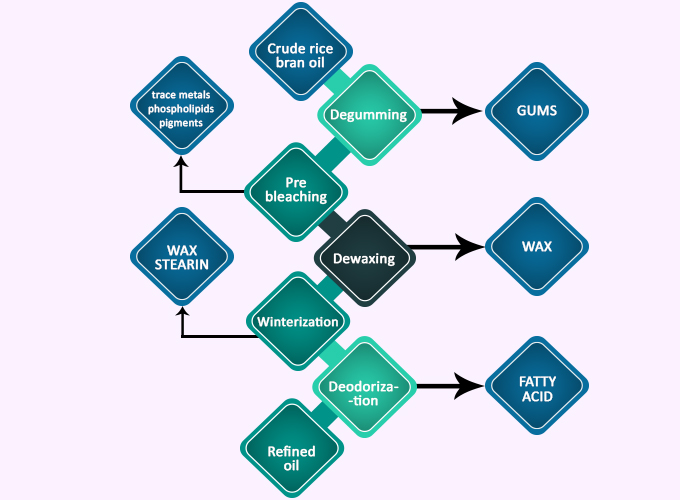

For the physical refining of Rice bran oil following processing steps takes place.

- Degumming

- Pre Bleaching

- Dewaxing

- Winterization (Optional)

- Post Bleaching

- Deodorization

Degumming of Rice Bran Oil

- Degumming eliminates phospholipids so as to enhance its physical stability. The process is necessary also to facilitate further steps in refining.

- Phospholipids can treat dark coloured oil and they can also serve as precursors of oil off -flavor. Free fatty acids, pigments and other impurities are also partially removed by degumming.

- The impurities have to be removed in the early refining stage for two main reasons

- As these cause high refining losses because of their emulsifying properties.

They decompose, and darken the oil because of their thermal instability.

Types of Degumming Suitable for Rice Bran Oil

- Acid degumming

- Enzymatic Degumming

Pre Bleaching Of Rice Bran Oil

“Bleaching” is a process of selective removal of pigments and impurities by the physical and chemical interaction of an adsorbent with an oil or fat to improve its quality.

- Colour pigments

- Dirt, Trace metals

- Removal of polycyclic Aromatic compounds

- Phospholipids

Dewaxing of Rice Bran Oil

Dewaxing of oil is a process of eliminating higher melting point constituents like waxes or triglycerides from oil by gradually cooling vegetable oils and separating saturated glycerides from the oil.

Normally Dewaxing process carried out at higher temperature (18-20 °C) to avoid the crystallization of saturated triglycerides & amalgamation of waxes & saturated triglycerides.

Winterization

Waxes & Saturated triglycerides which are fairly visible at low temperature are removed in this process to keep the appearance oil clean transform Degummed, Bleached & Dewaxed oil is cooled and filtered to achieve the quality.

Post Bleaching of Rice Bran Oil

This process refers to the art of removing

- Colour pigments

- Dirt, Trace metals

- Removal of polycyclic Aromatic compounds

- Phospholipids

Deodorization Of Rice Bran Oil

Deodorization achieves vacuum stripping by passing a specific amount of a stripping agent (usually steam) for a specific time through hot oil at low pressure. This is mainly a physical process that removes various volatile components.

Process Steps of Deodorization

Deodorization is a multi-step process comprising

- De-aeration

- Heating

- Deodorization cum De-acidification

- Cooling of the oil

Specification of Refined Rice Bran Oil

| FFA (As oleic acid) | 0.1% max |

| MOISTURE | Before Measurable Limits |

| U.S.M. | USM normally depends on the value of input oil parameter |

| TRANS FATS | 1.0% max |

| ORYZANOL | 10000 ppm min. |

| PEROXIDE VALUE | Nil for freshly refined oil |

| CLOD STABILITY @0°C | Oil shall be clear up to 5 1/2 hours |